In any laboratory, all equipment has a fundamental role in providing good sample quality, as well as appropriate analysis. Among all of them, though, one particularly crucial piece of equipment is the pH meter.

What is pH?

pH (Potential of Hydrogen) is a logarithmic scale that expresses the acidity or basicity of an aqueous solution.

Formula:

➡️ pH = –log₁₀(aH⁺)

- aH⁺ = hydrogen ion activity

| pH Value | Interpretation |

|---|---|

| < 7 | Acidic |

| = 7 | Neutral (at 25°C) |

| > 7 | Basic (Alkaline) |

Activity versus Concentration

pH influences analytical solution activity by dint of concentration. In ideal solutions, the concentration of a type (e.g., molarity, moles per liter) basically tells you how much of a substance is available to react. In practical solutions, especially at high concentrations or with added ions, a species’ effective concentration will not necessarily be equivalent to its analytical concentration. This effective concentration is known as activity (a).

Activity is responsible for interactions between ions and molecules, which may reduce their “freedom” to participate in chemical reactions. It is related to concentration (C) by the activity coefficient (γ):

a = γC

For very dilute solutions, the activity coefficient is nearly 1, so activity is roughly equivalent to concentration. But as concentration rises or ionic strength increases, γ deviates from 1, and activity must be used for exact thermodynamic calculations.

This is the Nernst Equation, which describes how pH works:

The Nernst equation is a fundamental equation of electrochemistry relating half-cell electrode potential or electromotive force of a full electrochemical cell with standard electrode potential, temperature, and activities of species participating. The Nernst equation can be utilized to calculate cell potentials under non-standard conditions.

For a general half-reaction:

Oxidized form + ne⁻ ⇌ Reduced form

The Nernst equation of electrode potential (E) is:

E = E₀ − (RT/nF) lnQ

Where:

- E is the electrode potential at non-standard conditions.

- E₀ is the standard electrode potential (standard conditions: 1 M activity of solutes, 1 atm gaseous partial pressure, 25°C).

- R = gas constant = 8.314 J/(mol·K).

- T stands for Kelvin temperature.

- n is the moles of electrons transferred within the half-reaction.

- F is Faraday’s constant, 96,485 C/mol of electrons.

- Q is the reaction quotient, or a measure of how active products are compared with reactants at any given time (similar to an equilibrium constant, except under non-equilibrium conditions).

At 25°C (298.15 K), changing from natural logarithm (ln) to base-10 logarithm (log₁₀), this equation simplifies to approximately:

E = E₀ − (0.0592/n) log₁₀Q (in Volts)

Types of PH meters

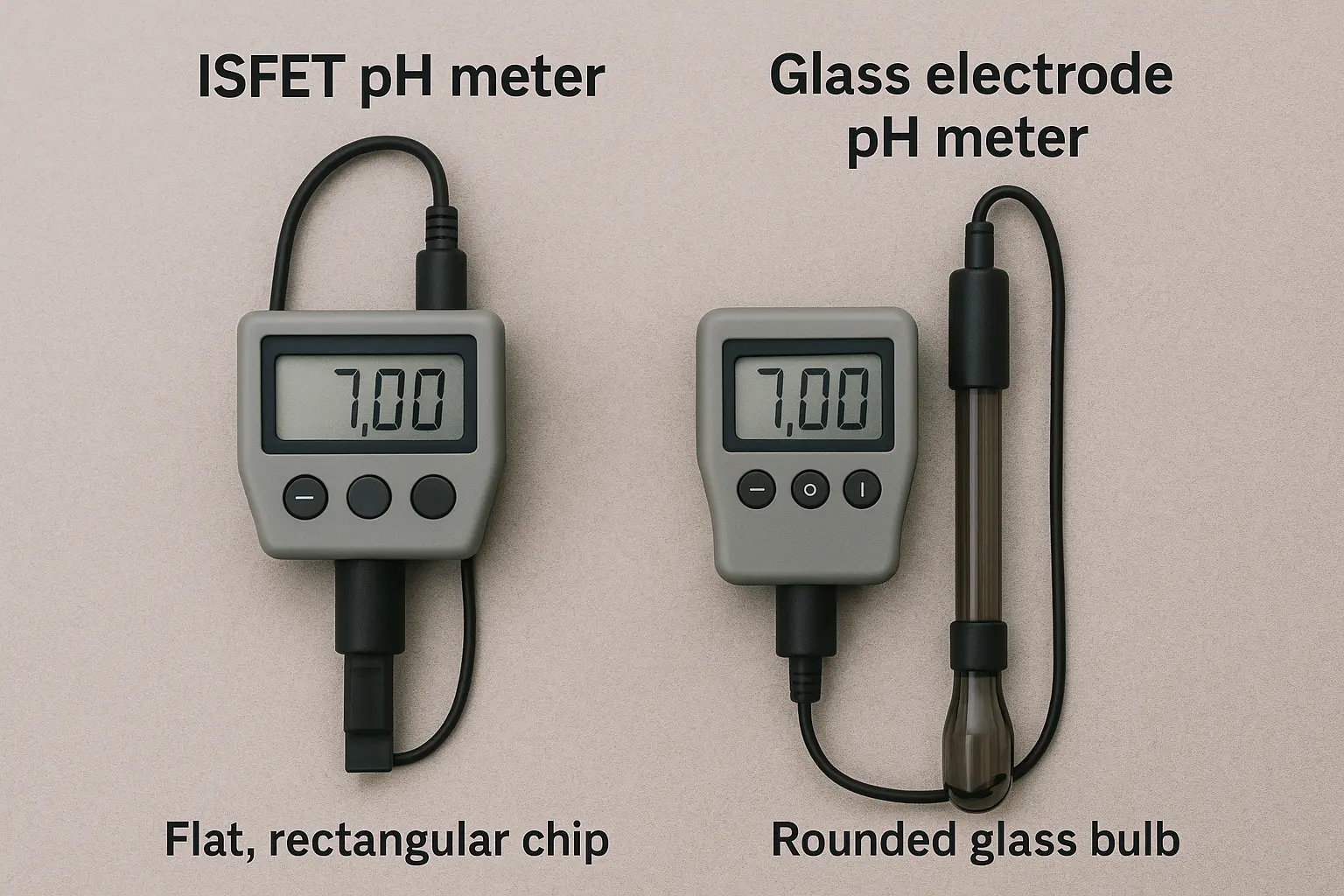

Which is the best glass electrode or ISFET pH meter for use in a pharmaceutical lab?

To answer this question, we need to know the difference between them:

1- Glass Electrode/Reference Electrode System and Potential Generation

A pH meter has a combination electrode, which integrates two main parts: a glass electrode (sensing electrode) and a reference electrode.

a-Glass Electrode (Sensing Electrode):

- The glass electrode is a proprietary thin pH-sensitive glass membrane (typically a bulb) with an internal solution of known, constant pH as 0.1 M HCl and an internal silver/silver chloride (Ag/AgCl) electrode.

- Submerged under a solution, hydrogen ions (H⁺) of the external solution replace alkali metal ions (such as Na⁺) within the hydrated layer of the glass membrane.

- This ion exchange creates a potential difference across the glass membrane that is directly proportional to the difference in hydrogen ion activity between the internal filling solution and the external sample solution. The more acidic the external solution, the greater the positive potential generated by the glass electrode relative to the reference.

b-Reference Electrode:

- The reference electrode (typically an Ag/AgCl electrode contained within a saturated KCl solution) provides stable and constant potential, regardless of sample solution contents.

- It contains a consistent internal solution and an internal electrode, and it’s designed to have a fixed and known half-reaction potential. A porous junction allows ionic contact with the sample solution without allowing the internal filling solution to mix significantly with the sample.

How the System Generates Potential:

The pH meter reports the voltage of the potential difference (voltage) between the reference electrode and the glass electrode. This voltage is largely a combination of a host of potentials, but of these, one of key importance is the one established across the pH-sensitive glass membrane, which varies with external hydrogen ion activity.

The interrelationship between sample-measured potential (Ecell) and sample pH is expressed by a modified Nernst equation as shown above. Or, more commonly, at 25°C and with the insertion of pH:

Ecell = K − 0.0592 × pH (where K includes reference potential and an asymmetry potential)

The pH meter then produces this voltage as a pH reading, based on this relationship, typically after calibration with buffer solutions of known pH. The constant reference electrode potential is a steady reference point against which this varying potential from the glass electrode can be measured with good precision.

2- Ion-Sensitive Field-Effect Transistor (ISFET)

The ISFET itself is the smallest chip that senses the ions, but without other components, especially a reference electrode and electronics, to function as a complete, practical pH sensor.

a-Reference Electrode:

To provide a steady reference potential as part of completing an electric circuit for measurement, an ISFET sensor will inevitably require a reference electrode. This is typically a silver/silver chloride (Ag/AgCl) electrode with an interior electrolyte (such as KCl) and a reference junction coming into contact with the sample solution.

B-Temperature Sensor:

Since pH is a function of temperature, almost all modern ISFET probes contain a temperature sensor such as a Pt1000 RTD. This way, you will automatically adjust and compensate the pH reading regarding changes you may have had concerning sample temperature, so you will end up with an accurate reading.

c-Probe Body/Housing:

The various components are encapsulated within a robust chemical-resistant housing, typically fabricated from plastics like ABS or PEEK (Polyetheretherketone). This protects electronics from damage and allows submergence within a sample.

d-Internal Electronics/Preamplifier:

The extremely fine electrical signals output from the ISFET chip due to pH changes need to be pre-amplified and conditioned. Most contemporary ISFET probes have built-in electronics, including a preamplifier, which preconditions the signal before sending it out to the pH meter. This produces a good, clean signal and can also allow calculations of temperature compensation.

Below is a comparison of the glass electrode and the ISFET to illustrate which one is preferable:

| Feature/Criteria | ISFET pH Sensor | Glass Electrode |

|---|---|---|

| Robustness/Durability | Solid-state, almost unbreakable. | fragile glass bulb. |

| Safety | No risk of glass contaminating products. | Risk of shards of glass contaminating samples/products. |

| Ease of Cleaning | Easier, more effective cleaning due to rugged design. | Normally, quicker response, good for real-time applications. |

| Storage | Can be stored dry; simplified maintenance. | Must be stored wet with proprietary solution; increased maintenance. |

| Response Time | It can truly be miniaturised with specialist applications. | Difficult cleaning of the fragile glass membrane. |

| Miniaturisation | Errors are minimised at extreme pH values. | Limited by having to fit a glass bulb. |

| Fouling Resistance | Less vulnerable to protein/sample biological fouling. | Susceptible to protein/sample fouling, with frequent cleaning. |

| Alkali/Acid Errors | Suitable for plant floor/in-process use due to ruggedness. | Can experience alkali/acid error at extremes of pH, with specialist glass required. |

| On-Site/In-Process Use | Normally, high initial cost. | Less suitable due to fragility. |

| Initial Cost | Usually, a lower initial cost. | Older/lower-end models a few years back may have less long-term stability/ultimate accuracy than high-end glass. (Improving quickly) |

| Stability/Accuracy | It can be sensitive to rapid changes in temperature, even with compensation. | High-quality ones have very good long-term stability and ultimate accuracy. |

| Temperature Dependence | Normally, a quicker response, good for real-time applications. | Normally robust against temperature changes once an equilibrium has been established. |

| Light Sensitivity | Can be sensitive to direct sunlight (semiconductor device). | Not affected at all by light. |

| Meter Compatibility | Special ISFET-compatible pH meters must be used. | Standard pH meters can be compatible. |

| Chemical Compatibility | Some chemicals can damage the ISFET chip itself (e.g., strong oxidizers). | Compatibility with a wide variety of chemicals, and less susceptible to direct chemical chip damage. |

| Familiarity | Less well-known newer technology. | Old, familiar technology. |

So, we can conclude that both the glass electrode and the ISFET PH sensor can be used in pharmaceutical applications. As each has its advantages and disadvantages, but considering that ISFET is predominantly improving.

Another factor to consider for pH is:

Calibration of PH meter

- Calibrating a pH meter is more than just a routine task. It’s a detailed process that involves understanding the electrochemistry, diagnosing electrode conditions, and ensuring accurate measurements. This means going beyond simply following instructions to understanding the underlying principles and interpreting the results correctly.

The goal of calibration is to identify the true E0 (offset) and slope of your specific electrode under your working conditions. No electrode is perfectly Nernstian, and its properties change over time and with use.

How to calibrate?

Buffer Selection: More Than Just “4, 7, 10”

☑️Range Coverage

When choosing pH buffers, think beyond the standard 4, 7, and 10. You should:

- Select buffers that match the expected pH range of your samples.

- For acidic samples (pH 2–5), use buffers like 1.68, 4.01, and 7.00—not 10.01.

☑️Number of Calibration Points

◾ Two-Point Calibration (Minimum)

- Example: 7.00 and 4.01 or 7.00 and 10.01.

- Establishes a linear relationship.

- Suitable for most routine applications.

◾ Three-Point Calibration (Most Common)

- Use 4.01, 7.00, and 10.01.

- It offers better linearity across a wider range.

- Helps detect electrode performance issues.

◾ Multi-Point Calibration (4+ Buffers)

- Ideal for high-precision applications or non-linear ranges.

- Especially useful at acid/base extremes.

- Advanced meters support segmented calibration for greater accuracy.

☑️Buffer Quality Matters

- Freshness: Buffers degrade, especially pH 10.01 (absorbs CO₂, lowers pH).

- Discard open bottles after 3–6 months.

- Never reuse calibration buffers.

- Certified Reference Materials (CRMs): Use buffers certified to ISO 17034 for maximum accuracy.

- Temperature Effects:

- Buffers are accurate at reference temperature (usually 25°C).

- Use ATC (Automatic Temperature Compensation) or input temperature manually for reliable results.

Temperature Control in pH Measurement

☑️ Automatic Temperature Compensation (ATC)

- The ATC probe measures buffer/sample temperature.

- Ensures correct Nernstian slope adjustment based on actual temperature.

☑️ Equilibration

- Buffers and samples should reach the ambient or set temperature.

- Sudden temperature changes = unstable or inaccurate readings.

Electrode Preparation & Handling: Beyond Just Rinsing

☑️ Rinsing Technique

- Rinse with distilled or deionized water between buffers.

- Use a clean rinse bottle.

- Gently blot with a lint-free tissue—don’t rub.

☑️Soaking & Conditioning

- Soak in storage solution or pH 7.00 buffer before calibration.

- Duration: From minutes to several hours, depending on previous storage conditions.

- Ensures the hydration layer on the glass membrane is restored.

☑️ Reference Junction Flow

- For refillable electrodes: keep the fill hole open during use.

- Understand how junction type (ceramic, annular, sleeve) impacts flow and potential clogging.

Interpreting Calibration Data

☑️ Slope (mV/pH or % of Nernstian)

- Ideal Slope: -59.16 mV/pH (100%) at 25°C.

- Acceptable Range: 95–105% (or 56–62 mV/pH).

Interpretation

- Low Slope (<90%)

- Causes: fouled, aging, or dehydrated electrode.

- Fix: clean, recondition, or replace.

- High Slope (>105%)

- Less common, but can indicate issues with the reference electrode, short circuits, or contamination.

- Non-Linearity

- If the slope varies significantly between calibration segments, it suggests non-ideal behavior, possibly due to acid/alkaline errors or a deteriorating glass membrane.

☑️ Offset (mV at pH 7.00)

- Ideal: 0 mV.

- Acceptable Range: ±30 mV (some sources allow up to ±50 mV).

Interpretation:

Significant Deviation from 0 mV: Indicates a shift in the asymmetry potential of the electrode. This can be due to coating of the glass membrane, changes in the internal reference electrode, or issues with the reference junction. A large offset often precedes slope issues. Corrective action: cleaning, reconditioning, or replacement.

☑️Isopotential Point

- Normally at pH 7.00 and 0 mV.

- A large deviation = potential temperature compensation errors.

- This is the pH value at which the electrode’s potential is theoretically independent of temperature. For most common electrodes, it’s designed to be around pH 7.0 and 0 mV.

- While not usually displayed directly as a calibration parameter, a proficient user understands its theoretical significance, especially when dealing with samples at varying temperatures. A significant shift in the actual isopotential point from the ideal can lead to temperature compensation errors

☑️Response Time & Stability

- Healthy electrode: stabilizes in 30–60 seconds.

- During Calibration, you should observe how quickly the reading stabilizes in each buffer. Rapid stabilization is usually within 30 seconds to a minute, which is a sign of a healthy electrode.

- Slow Stabilization/Drift: Indicates a slow-responding, dirty, or failing electrode, often due to a clogged reference junction.

- Dirty junction

- Clogged reference

- Failing electrode

Post-Calibration Verification & Record Keeping

- Check Standard: After calibrating the pH meter, measure a fresh buffer (ideally one not used for calibration, or one at a different temperature if ATC is in use) to verify calibration accuracy. Typically, this involves measuring buffer 7. The reading should be within a specified tolerance of ±0.02 or ±0.05 pH units of the buffer’s known value.

- Calibration Log: documentation is crucial. Record:

- Date and time of calibration

- Buffers used (lot numbers, expiration dates)

- Electrode serial number

- Calibrated slope and offset values

- Temperature

- Operator’s initials

- Any notes on electrode performance or issues

For more information, check the calibration of PH meter in the ISO accreditation

Let’s thoroughly explore calibration:

When do we make a calibration?

Calibration is not just “daily” or “weekly” but based on a risk assessment:

- Before Critical Measurements: Always.

- After Electrode Maintenance: After cleaning, reconditioning, or replacing the electrolyte.

- If Readings are Suspect: If internal QC checks fail, or sample readings are unexpected.

- After a Period of Non-Use, Even if stored correctly, electrodes need to re-equilibrate.

- If Sample Temperature Changes Significantly: Especially if not using ATC, or if the ATC is suspected.

- As Electrode Ages: Older electrodes drift more and require more frequent calibration.

- As Dictated by SOPs/Accreditation: These are minimum requirements for a reason.

By mastering the science behind pH meter calibration and diligently interpreting the data, users can move beyond simply operating the instrument to truly understanding and controlling their pH measurement process, ensuring the highest level of accuracy and reliability.

pH Meter Errors and How to Deal with Errors?

Five critical errors that can arise during the use of a pH meter

pH meters are essential tools for many applications, but they can be prone to errors that lead to inaccurate readings. Here’s a breakdown of common pH meter errors, their causes, and how to troubleshoot them, Let’s now talk about the most common errors that are going face:

1- inaccurate reading:

Actually it is a big problem, that the actual reading doesn’t match what appeared to you on the screen.

So, in this case, it will greatly affect the job you are adjusting for it the pH.

2- unstable reading:

When the reading fluctuates or takes an unusually long time to stabilize.

3- Slow Response Time:

This means that it takes too much time to reach a stable reading.

4- ph meter malfunction:

Where the pH shows error or no value appears.

5- Acid/alkilne error:

Where a deviation occurs from the nernest equation at very low values

How to deal with these errors?

Primary Causes of pH Meter Errors:

- Improper or Infrequent Calibration: This is the most frequent cause of inaccuracy.

- Expired or Contaminated Buffer Solutions: Buffers degrade over time, especially pH 10.01 buffer due to CO2 absorption. Using old or contaminated buffers will result in an incorrect calibration.

- Incorrect Calibration Procedure: Not following the manufacturer’s instructions, calibrating in the wrong order (always calibrate with pH 7.01 first), or not rinsing between buffers.

- Temperature Mismatch: Calibrating and measuring at different temperatures without automatic temperature compensation (ATC), or if the ATC function is faulty. pH is temperature-dependent.

- Electrode Issues: The pH electrode (probe) is the most delicate and critical part.

- Contamination/Dirty Electrode: Buildup of sample residues (fats, proteins, minerals) on the sensing glass or clogged reference junction. This hinders the electrode’s ability to respond accurately.

- Dehydration/Dry Storage: Storing the electrode dry or in distilled/deionized (DI) water. DI water can cause an osmotic effect, depleting the internal electrolyte solution and damaging the electrode. Always store in a proper storage solution (e.g., 3M KCl or specific pH electrode storage solution).

- Aging/Expired Electrode: pH electrodes have a limited lifespan (typically 12-18 months), even with proper care, as the glass membrane degrades over time.

- Physical Damage: Cracks, leaks, or a broken glass bulb on the electrode.

- Low Electrolyte Solution: For refillable electrodes, the internal electrolyte solution may be low or contaminated.

- Incorrect Electrode Type: Using an electrode not suited for the sample type (e.g., highly viscous solutions, specific temperatures).

- Environmental Factors:

- Temperature Variations: As mentioned above, temperature significantly affects pH readings. Ensure samples and buffers are at the same temperature or use a meter with effective ATC.

- Electrical Interference: External electrical noise from nearby equipment (motors, stirrers, power supplies) can interfere with the high-impedance measuring circuit of the pH meter.

- Improper Sample Handling: Not mixing samples thoroughly, cross-contamination between samples, or not submerging the electrode completely in the sample.

- Meter Malfunction:

- Low Battery: Can lead to inaccurate readings or no reading at all.

- Loose or Damaged Cable Connections: Affects signal transmission between the electrode and the meter.

- Internal Circuitry Issues: Less common, but possible, such as a faulty memory chip or measurement unit.

Troubleshooting and Prevention:

- Regular Calibration: Calibrate your pH meter frequently, especially before critical measurements or if you suspect inaccuracies. Always use fresh, high-quality buffer solutions.

- Proper Electrode Storage: Store the electrode in a dedicated pH electrode storage solution (not DI water) when not in use. Ensure the cap is filled.

- Thorough Cleaning: Clean your electrode regularly using appropriate cleaning solutions as pepsin-HCl for protein, thiourea for silver sulfide, or general-purpose cleaning solutions. Rinse with distilled water between measurements.

- Inspect for Damage: Visually inspect the electrode for any cracks, leaks, or visible contamination.

- Check Electrode Age: Note the manufacturing date or purchase date. Replace electrodes past their typical lifespan.

- Ensure Proper Submersion: Make sure the entire sensing part of the electrode is fully submerged in the sample or buffer.

- Temperature Control: Allow samples and buffers to equilibrate to the same temperature. Use a meter with ATC if measuring at varying temperatures.

- Minimize Electrical Interference: Keep the pH meter away from other electrical equipment that could generate interference.

- Check Connections and Battery: Ensure all cables are securely connected and replace batteries if they are low.

- Consult the Manual: Always refer to your specific pH meter’s user manual for detailed troubleshooting steps and maintenance recommendations.

- Test with a Known Solution: If you suspect your meter, test it with a freshly prepared solution of known pH (e.g., distilled water, which should be around 7 if exposed to air).

By understanding these common errors and implementing proper maintenance and troubleshooting techniques, you can significantly improve the accuracy and reliability of your pH measurements.

Also any lab needs to perform the proficeny test to ensure ongoing accuracy and compliance. Here’s a breakdown of when it’s typically recommended or required:

1. For Accreditation (by ISO/IEC 17025):

2- maintaining accredation:

3–As Part of a Quality Management System (QMS):

Even if not formally accredited, any laboratory committed to quality like to following GMP, GLP ,should implement PT.

what is the relation between PH accuracy and the quality of work?

PH is a critical step in R&D and analysis, generally in the pharmaceutical field:

1- It will affect the solubility and dissolution of the drug. For R&D, it will affect the formulation and subsequent absorption in the body. Bioavailability, where the effect is great, as the drug’s ability to dissolve is the first step towards its absorption and bioavailability. If a drug’s solubility is compromised due to incorrect pH, its dissolution rate will affect the Stability of the drug, which is greatly affected by PH.

2- Drug Efficacy and Biological Activity where the PH affects either in vivo or in vitro. For example, oral drugs must navigate the varying pH environments of the gastrointestinal tract (acidic stomach, more alkaline small intestine). Formulations are designed to release the drug effectively at specific pH values to maximize absorption and targeting.

3- pH plays a pivotal role in analytical procedures, as an incorrect pH can compromise the entire method, preventing proper separation of the analyte. You can check more on this in this article: Your Guide to Select the buffer in HPLC development part

In conclusion, pH accuracy is not merely an analytical measurement in pharmaceutical R&D; it is a fundamental parameter that underpins the safety, efficacy, and quality of every drug product. The diligent work of analysts, coupled with strict adherence to GLP guidelines and advanced instrumentation like pH meters and ISFETs, is indispensable in navigating the complex pH landscape of drug development and ensuring robust, reliable, and patient-safe pharmaceutical innovations

References:

1- Sorensen, S.P.L. (1909). Introduction of the pH concept. Biochemische Zeitschrift.

2- Nernst, W. (1889). Development of the Nernst equation. Zeitschrift für Physikalische Chemie.

3- Haber, J., & Klemensiewicz, Z. (1909). Development of the glass electrode for pH measurement. Zeitschrift für Elektrochemie.

4- Contributions to electrochemistry: Advancements in electrode potentials and activity coefficients during the late 19th and 20th centuries. Electrochemistry Explained: From Fundame

5- Proficiency testing for pH measurement: A 3-year evaluation. (2018). Accreditation and Quality Assurance, https://link.springer.com/article/10.1007/s00769-018-1362-4.

6- Estimation of the uncertainty of pH measurement results: A direct pathway to quality assurance. (n.d.). ProQuest Dissertations, https://www.proquest.com/openview/1cb99391bd417c0455ed1c4e77eeac80/1?pq-origsite=gscholar&cbl=2026366&diss=y.

7- 50 years of ISFET – Unbreakable pH sensors. (n.d.). Endress+Hauser Learning Center, https://www.us.endress.com/en/support-overview/learning-center/ISFET-technology-pH-measurement.

8- The ion-sensitive field-effect transistor (ISFET) pH electrode: A new sensor for long-term ambulatory pH monitoring. (n.d.). National Center for Biotechnology Information (NCBI), https://pmc.ncbi.nlm.nih.gov/articles/PMC1378826/.

9- Enhancing pH prediction accuracy in Al₂O₃-gated ISFETs using XGBoost regressor and stacking ensemble learning. (n.d.). NCBI, https://pmc.ncbi.nlm.nih.gov/articles/PMC12127451.

9- Calibration according to ISO/IEC 17025. (n.d.). Scribd, https://www.scribd.com/document/694627368/Calibration-According-to-ISO-IEC-17025-1703284849.

10- Sinha, Soumendu, Pal, Tapas, (2022), ISFET sensor characterization