Introduction

In today’s fast-paced and hyper-competitive global marketplace, the phrase “learning never stops” has evolved from a motivational slogan into a survival strategy. Nowhere is this truer than in industries where precision, compliance, innovation, and efficiency are non-negotiable such as pharmaceuticals, biotechnology, healthcare, and manufacturing. At the heart of this dynamic reality lies a fundamental pillar of Operational Excellence: Continuous learning and training.

Operational Excellence is not a one-time initiative or a departmental responsibility. It is a company-wide philosophy, a commitment to doing things better, smarter, and more sustainably across all levels and functions. While process improvement, Lean Six Sigma, visual management, and data-driven decision making often steal the spotlight in operational excellence conversations, the foundational driver of all these elements is people. And people evolve only through learning.

This article explores continuous learning and training as a strategic lever for sustained operational excellence. By the end of this article, you will understand why embedding a culture of continuous learning and training is not just an HR priority; it is an operational imperative.

What is Continuous Learning and Why is it foundational to Operational Excellence?

At its core, continuous learning refers to the ongoing, voluntary, and self-motivated pursuit of knowledge and skills. It spans across technical competencies, behavioral insights, cross-functional knowledge, and leadership development. Meanwhile, training is the structured delivery of this knowledge through methods like workshops, e-learning, mentorship, simulations, and on-the-job instruction.

Together, continuous learning and training form a dual engine that drives human capital development, agility, innovation, and problem-solving. All of which are essential components of a high-performing Operational excellence environment.

Continuous Learning in the Context of Operational Excellence:

In operational excellence frameworks, such as The Shingo Model and The Toyota Production System, the learning and development of employees are considered sacred. Companies committed to Operational excellence understand that:

- No process is ever perfect.

- No standard is ever final.

- No employee has learned everything.

Therefore, they cultivate an environment in which every person, every day, is a learner. This mindset transforms a company into a self-improving organism that evolves with the market, technology, and customer expectations.

Why Continuous Learning Matters in the Pharmaceutical Industry?

1. Navigating Regulatory Complexity:

Pharmaceutical companies operate in a regulatory environment that is both stringent and dynamic. Good Manufacturing Practice (GMP), Good Laboratory Practice (GLP), ICH guidelines, and pharmacovigilance regulations are frequently updated. Failing to train employees on the latest procedures or compliance expectations can result in warning letters, product recalls, or even market bans.

2. Keeping Up with Scientific and Technological Advancements:

From AI-driven drug discovery to Pharma 4.0, the pharmaceutical field is undergoing a scientific revolution. This means that R&D scientists, process engineers, QC analysts, and QA auditors must continuously improve and keep themselves updated.

3. Building Resilience:

The pharmaceutical sector needs specialized talents in quality, regulatory affairs, statistics, complex supply chains, and data analytics. Organizations that prioritize internal development are better positioned to build talent pipelines, reduce attrition, and close skill gaps without always relying on external recruitment.

Theoretical Foundations of Continuous Learning:

1. Learning Organization Theory (Peter Senge):

In his book “The Fifth Discipline”, Peter Senge introduced the concept of a “learning organization”. An organization where people always expand their capacity to create the needed results. Senge proposed five disciplines:

1.1. Personal Mastery:

Personal mastery is the discipline of self-improvement and growth. It involves developing a clear personal vision, identifying gaps between current reality and that vision, and bridging those gaps through disciplined learning. Individuals who practice personal mastery are deeply committed to learning, not just to enhance their skills but to expand their capacity to create desired outcomes in life and work. In an organizational context, personal mastery empowers employees to take initiative, demonstrate resilience, and contribute meaningfully to strategic goals. Organizations that support personal mastery cultivate a workforce that is both competent and purpose-driven.

1.2. Mental Models:

Mental models are the ingrained assumptions, beliefs, and generalizations that shape how we perceive the world and act within it. These internal frameworks influence decision-making and behavior subconsciously. The discipline of working with mental models involves becoming aware of these assumptions, critically examining them, and being open to alternative perspectives. In leadership and team dynamics, challenging outdated mental models fosters adaptability, innovation, and improved problem-solving. Organizations that encourage this discipline create cultures of transparency, critical thinking, and continuous improvement.

1.3. Shared Vision:

A shared vision is a collective goal that unites members of an organization toward a common future. Unlike top-down directives, a true shared vision emerges through collaboration and reflects the hopes and values of all stakeholders. It serves as a guiding force that aligns individual efforts with organizational objectives and ensures commitment. When employees feel personally invested in the vision, they are more motivated, engaged, and willing to overcome challenges. Leaders who adopt shared vision build cohesive, high-performing teams that pursue excellence with clarity and purpose.

1.4. Team Learning:

Team learning is the process by which teams collectively develop the ability to produce desired results through collaboration and shared experiences. It extends personal mastery into a group context, emphasizing the importance of aligning individual efforts and enhancing collective intelligence. Effective team learning requires open communication, trust, and a safe environment for constructive feedback. As teams learn together, they not only improve performance but also foster creativity, innovation, and agility. Organizations that prioritize team learning can better adapt to change and leverage the strengths of diverse perspectives.

1.5. Systems Thinking:

Systems thinking is the cornerstone discipline that integrates the others. It involves understanding the organization as a complex, interconnected system rather than a collection of isolated parts. This perspective helps individuals see patterns, interdependencies, and the root causes of issues, rather than just addressing the symptoms. Systems thinking encourages long-term thinking, strategic alignment, and more effective decision-making. When embraced by an organization, it promotes holistic problem-solving and sustainable solutions, enabling the organization to navigate complexity with greater foresight and coherence.

These principles align perfectly with Operational Excellence, especially in how they emphasize collaboration, continuous improvement, and problem-solving.

2. Kolb’s Experiential Learning Cycle:

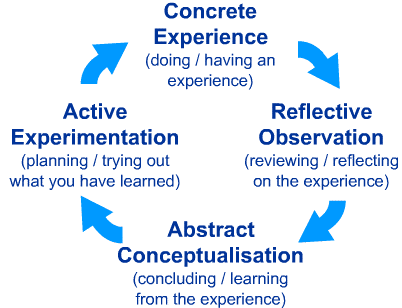

Kolb’s theory suggests that learning is a continuous cycle, and that learners can enter the cycle at any stage. By understanding these stages, corporations can design learning experiences that cater to different learning preferences and promote deeper engagement.

This model frames learning as a four-stage cycle:

2.1. Concrete Experience:

This is the initial stage where the learner has a new experience or reinterprets an existing one. It’s about engaging in the learning material in a hands-on way.

2.2. Reflective Observation:

In this stage, the learner reflects on the experience, considering what happened and why. This involves thinking about the experience from different perspectives and drawing personal meaning from it.

2.3. Abstract Conceptualization:

This stage involves forming abstract concepts and theories based on the reflections from the previous stage. It’s about making sense of the experience and developing a deeper understanding of the underlying principles.

2.4. Active Experimentation:

Finally, the learner actively tests these newly formed concepts and theories in new situations. This stage involves applying the knowledge gained and experimenting with different approaches to see what works best.

Pharma companies applying continuous improvement methodologies like Lean or Six Sigma benefit from aligning training programs with experiential learning such as kaizen events, process simulations, or Gemba walks.

3. The 70-20-10 Model:

Widely used in corporate learning, this model suggests:

- 70% of learning comes from on-the-job experiences.

- 20% from social learning (mentoring, coaching).

- 10% from formal training (courses, seminars).

This reinforces the idea that companies need to design learning ecosystems, not just deliver classroom sessions.

How to build a Culture of Continuous Learning?

1. Leadership Commitment:

Senior leaders must walk the talk by:

- Regularly attending training sessions.

- Sharing their own learning goals.

- Allocating budget to accommodate training programs.

“A leader is one who knows the way, goes the way, and shows the way”

2. Learning as a Performance Expectation:

When learning is positioned as a core performance expectation, it shifts from being a peripheral activity to a central driver of organizational success. Organizations that embed learning into performance metrics see stronger adoption. By setting targets related to training completion, skill development, or competency acquisition, companies reinforce the value of learning and make it a tangible part of everyday work. This approach not only promotes accountability but also fosters a culture where curiosity and self-development are recognized and rewarded. Moreover, aligning learning goals with performance appraisals helps create a more agile and future-ready workforce. Employees are more motivated to engage in learning when it directly impacts their career progression, recognition, or role advancement.

3. Psychological Safety:

People are more likely to learn when they feel safe admitting ignorance or asking questions. Teams with high psychological safety innovate faster, learn better, and recover from errors more effectively.

Digital Learning in the Age of Pharma 4.0:

A. Learning Management Systems (LMS):

Learning management systems are software that are used for planning, tracking, reporting, automation, and delivery of educational courses and training programs. Modern LMS platforms transform how pharma employees consume training content. Features include:

- Role-based training.

- Gamification.

- Mobile learning.

B. Virtual Reality (VR) and Augmented Reality (AR):

Virtual Reality (VR) and Augmented Reality (AR)are revolutionizing how pharmaceutical companies approach training, production, quality assurance, and patient engagement. VR creates immersive, simulated environments that allow employees to be trained in complex procedures like aseptic operations or equipment handling without the risks or costs associated with real-world exposure. This not only improves learning outcomes but also accelerates onboarding and competency development in GMP-regulated environments. In highly controlled environments such as cleanrooms, VR reduces the need for physical presence during training, minimizing contamination risks and material waste.

AR, on the other hand, enhances real-world operations by overlaying digital information onto physical environments through smart glasses or mobile devices. In manufacturing and quality control, AR can guide technicians through step-by-step SOPs, ensure compliance through real-time validation, and reduce human error by providing contextual instructions during critical tasks. Maintenance teams benefit from remote AR-assisted troubleshooting, reducing downtime and dependency on on-site experts. By merging digital data with physical actions, AR supports a more connected, data-driven, and compliant workforce, aligning seamlessly with the Pharma 4.0 vision of an integrated and intelligent ecosystem.

Beyond operations, VR and AR also play a growing role in patient-centric initiatives and R&D. Virtual clinical trial simulations help optimize protocol design and improve patient recruitment strategies. AR applications can educate patients on medication usage, visualize drug mechanisms, and even support remote diagnosis or therapy adherence, enhancing engagement and outcomes. In drug discovery, VR is used to model complex molecular structures, allowing researchers to interact with compounds in 3D space, accelerating innovation. Ultimately, the integration of VR and AR into Pharma 4.0 enhances efficiency, safety, and innovation across the pharmaceutical value chain.

C. AI-Powered Adaptive Learning:

AI-powered adaptive learning is becoming a cornerstone of workforce development in Pharma 4.0, where continuous upskilling is essential to keep pace with rapidly evolving technologies and regulatory demands. Unlike traditional one-size-fits-all all training methods, adaptive learning systems use artificial intelligence to personalize educational content based on each learner’s pace, career pathway, performance, and knowledge gaps. This approach enhances knowledge retention, ensures competency in critical areas like GMP compliance, data integrity, and process validation, and accelerates time-to-proficiency for both new hires and existing staff.

In highly regulated pharmaceutical environments, AI-powered learning platforms can dynamically adjust training modules in response to new guidelines, audit findings, or process changes. For example, if a deviation trend is observed in a particular manufacturing process, the system can push targeted microlearning modules to affected personnel in real time. Additionally, these platforms can simulate real-life decision-making scenarios, offer immediate feedback, and reinforce critical thinking and risk-based approaches aligned with regulatory expectations. The result is a smarter, more resilient workforce that evolves alongside the processes and technologies it supports.

Beyond internal training, AI-adaptive learning can also improve knowledge transfer in broader Pharma 4.0 contexts, such as supplier education, cross-functional collaboration, and patient-focused programs. By analyzing user behavior, engagement levels, and comprehension patterns, AI can predict training outcomes and suggest interventions before performance issues arise. This proactive model not only ensures compliance and quality standards but also fosters a culture of continuous learning and operational excellence. As pharma companies embrace digital transformation, AI-powered learning ecosystems will be essential to building a future-ready workforce capable of thriving in an intelligent, connected pharmaceutical environment.

What are the barriers to Continuous Learning in Pharma corporations?

1. Time and Workload Pressures:

In many pharmaceutical sites, employees are stretched thin. Finding time for training between audits, batch releases, or validation activities is a challenge.

2. Overemphasis on Compliance:

Sometimes, training becomes a tick-box exercise. Employees sit through hours of mandatory courses just to stay “qualified” but don’t actually retain or apply knowledge.

3. Resistance to Change:

Especially among seasoned experts, there can be a perception that training is for juniors. Overcoming ego and fixed mindsets is a cultural transformation, not just a scheduling issue.

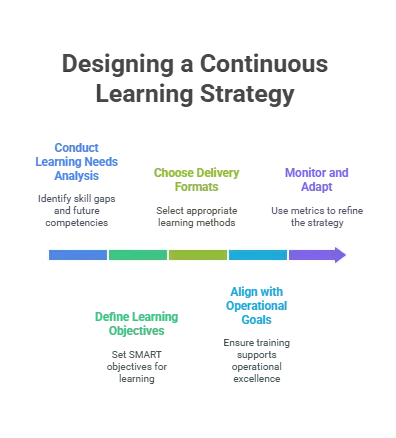

How to Design a Continuous Learning Strategy?

Step 1: Conduct a Learning Needs Analysis

Identify skill gaps, role transitions, and future competencies using surveys, interviews, and performance data.

Step 2: Define Learning Objectives

Make them SMART — Specific, Measurable, Achievable, Relevant, and Time-bound.

Step 3: Choose Delivery Formats

Mix e-learning, instructor-led sessions, mentoring, simulations, and peer learning groups.

Step 4: Align with Operational Excellence Goals

Ensure training supports Kaizen initiatives, audit readiness, tech transfer, or data integrity improvements.

Step 5: Monitor and Adapt

Use metrics like learning transfer, behavioral change, and operational KPIs to refine the strategy.

Conclusion:

In the journey toward Operational Excellence, continuous learning and training are not just tools; they are strategic assets. They build capability, drive engagement, and future-proof the workforce. Most importantly, they unleash the potential of human intelligence, which is the most valuable resource any organization possesses.

In pharma, where the cost of error is high and the rate of change is accelerating, learning must be relentless, relevant, and rewarding. Training programs should no longer be static or compliance-driven. They must be integrated into daily work, aligned with strategic goals, and delivered in formats that inspire curiosity and mastery.

Organizations that invest in continuous learning don’t just outperform. They outlast.

References

- Senge, P. M. (1990). The Fifth Discipline: The Art and Practice of the Learning Organization.

- Kolb, D. A. (1984). Experiential Learning: Experience as the Source of Learning and Development.

- Liker, J. K. (2004). The Toyota Way fieldbook.