Dry granulation is a cornerstone technique in pharmaceutical manufacturing, offering a robust solution for producing solid dosage forms, especially when dealing with active pharmaceutical ingredients (APIs) and excipients that are sensitive to moisture or heat. Unlike wet granulation, this method bypasses the need for liquid binders, relying instead on mechanical compression to achieve particle agglomeration and densification. This approach not only preserves the integrity of sensitive materials but also streamlines the manufacturing process.

Why do we choose dry Granulation?

Dry granulation is strategically employed in scenarios where traditional wet granulation methods are unsuitable or less efficient. Its primary advantages include:

- Moisture and Heat Sensitivity: It is the preferred method for materials that degrade in the presence of water, organic solvents, or elevated temperatures, safeguarding their chemical stability and potency.

- Cost and Time Efficiency: By eliminating the need for drying steps, dry granulation significantly reduces energy consumption, processing time, and associated costs, making it an economically attractive option.

- Enhanced Material Properties: This technique effectively transforms poorly flowing powders into free-flowing granules and improves the compressibility of materials, which is crucial for efficient tableting.

- Reduced Contamination Risk: Operating as a closed system, dry granulation minimizes the potential for cross-contamination and environmental exposure, ensuring product purity and safety.

Key Formulation Considerations

The success of dry granulation largely depends on a meticulous understanding of the API’s characteristics and the strategic selection of excipients. Critical factors include:

- API Properties: The intrinsic properties of the API, such as particle size, morphology, crystallinity, and deformation behavior (brittle vs. plastic), profoundly influence the granulation outcome. APIs exhibiting plastic deformation generally compact more effectively.

- Excipient Roles: Excipients are indispensable for achieving desired granule and tablet attributes.

- They serve various functions:

- Diluents/Fillers: These provide bulk to the formulation and can significantly impact compactibility (e.g., lactose, microcrystalline cellulose).

- Binders: Essential for imparting cohesive strength to the granules, ensuring they remain intact (detailed further below).

- Disintegrants: Facilitate the breakdown of tablets and subsequent drug release in the body

- Lubricants: Minimize friction during the compaction and ejection phases, though their excessive use can sometimes compromise tablet strength.

- Glidants: Enhance powder flow properties, ensuring consistent feeding into the compaction equipment.

- They serve various functions:

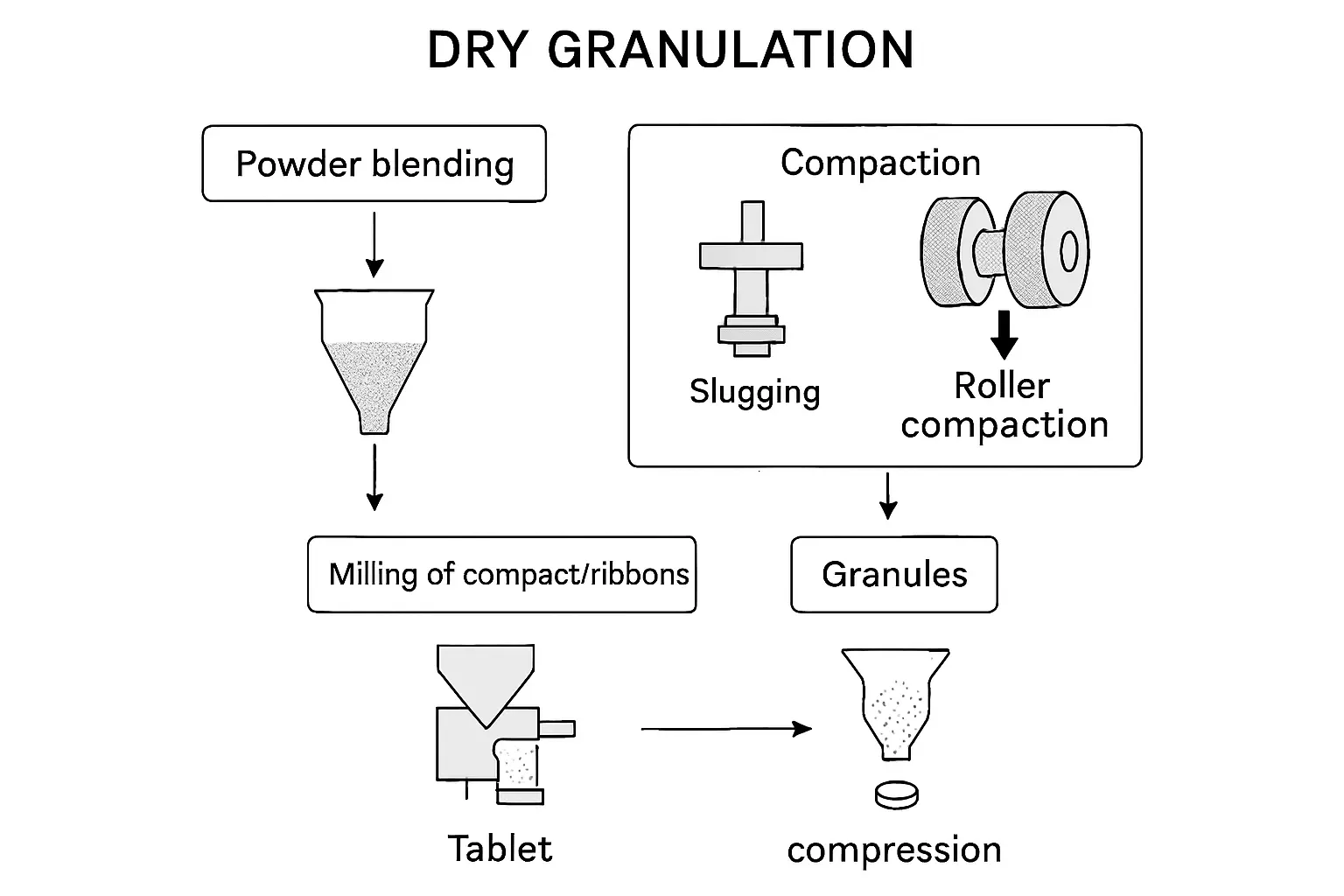

The Dry Granulation Process: Slugging vs. Roller Compaction

Overall Dry Granulation Process

Dry granulation is primarily executed using two distinct equipment types, each with its own methodology and advantages:

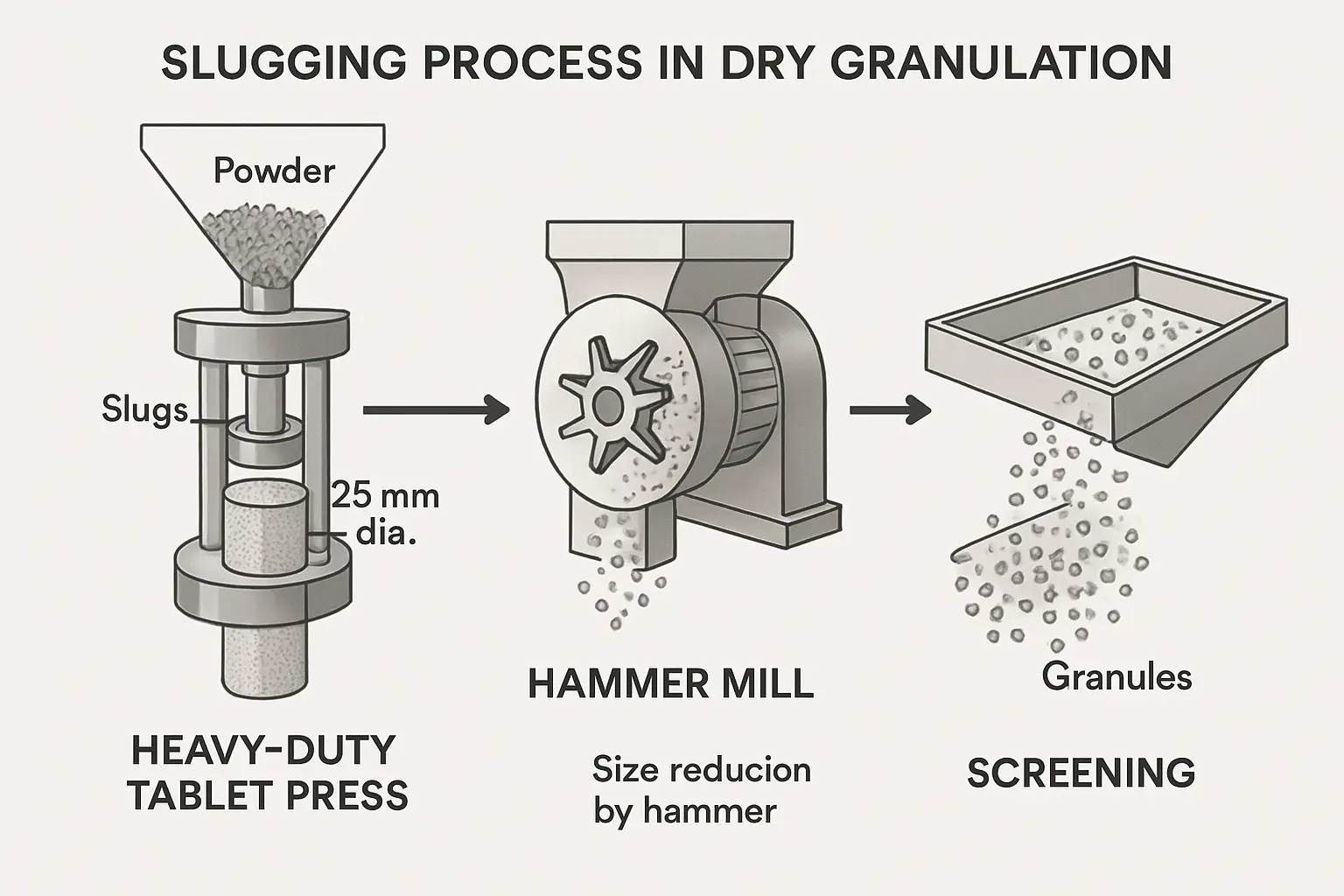

1. Slugging

Slugging represents the older, more conventional approach. It involves compressing dry powder into large, dense compacts, known as “slugs,” using a heavy-duty tablet press. These slugs are then subsequently milled into granules.

Process Overview:

- Compaction: Powder is fed into a tablet press and subjected to high pressure to form slugs (typically 25 mm in diameter and 10-15 mm thick).

- Milling: The formed slugs are then broken down into granules using a hammer mill.

- Screening: Granules are sieved to achieve the desired particle size distribution, with any fine particles often recycled back into the process.

Advantages:

This method is relatively straightforward and can be cost-effective for smaller production batches.

Slugging can sometimes lead to non-uniform densification, especially with poorly flowing powders. It also involves significant equipment wear due to the high forces applied and can generate considerable dust during the milling phase.

For a trusted and detailed explanation of the slugging dry granulation process, visit this informative guide by Pharmaguideline. Learn more about slugging in dry granulation.

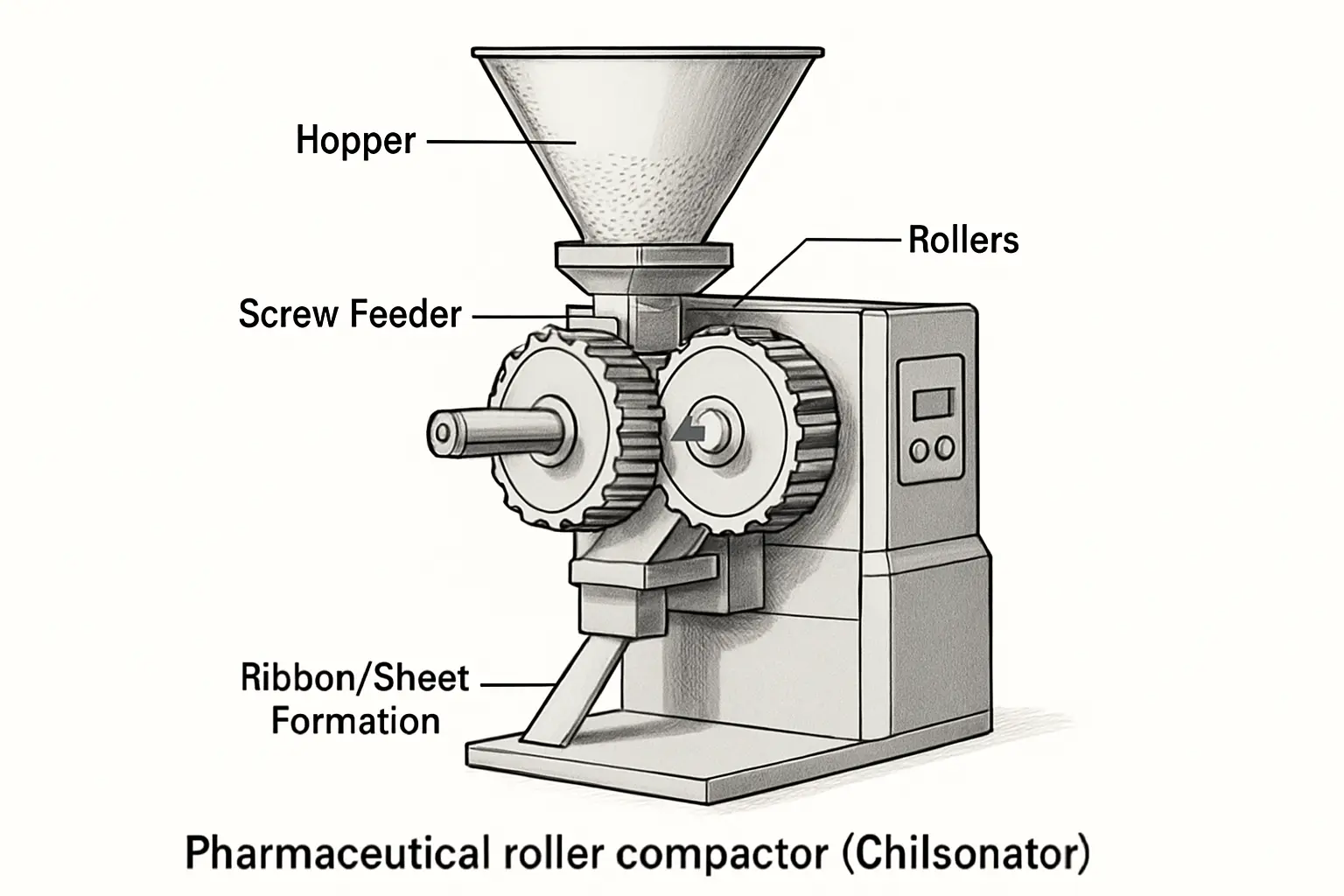

2. Roller Compaction

Roller compaction is a more contemporary and widely adopted method, favored for its continuous operation and superior process control. It involves feeding powder between two counter-rotating rollers, which compress the material into a dense ribbon or sheet. This ribbon is then milled into granules.

Process Overview:

- Feeding: The powder blend is precisely fed into the compaction rollers, often facilitated by a screw feeder to ensure consistent delivery.

- Compaction: The rollers apply pressure, transforming the powder into a compact ribbon.

- Milling/Granulation: The brittle ribbon is then broken into flakes and subsequently milled into granules of the desired size.

- Screening: The resulting granules are screened, and fine particles can be recycled to maintain efficiency.

Advantages:

This is a continuous process, offering enhanced control over critical parameters such as compaction force, roll speed, and gap width. It generally results in less dust generation during the compaction stage.

Optimization & Tricks:

- Achieving optimal results with roller compaction requires precise control of compaction force, roll speed, and gap width.

- Consistent material feed rates are paramount.

- The design and surface characteristics of the rollers can significantly impact efficiency.

- Effective degassing is crucial for certain materials to prevent air entrapment.

- For challenging materials, repeated compaction steps might be necessary to achieve the desired granule properties.

The role of Binders and Fillers

Binders are indispensable in dry granulation, providing the necessary cohesive strength to the compacted material. Unlike wet granulation, dry granulation exclusively utilizes dry binders. Fillers, on the other hand, contribute bulk to the formulation and can influence the material’s compactibility

Common Dry Binders:

Microcrystalline Cellulose (MCC): A highly versatile and widely used dry binder, renowned for its excellent compactibility and flow properties

- Cellulose-based polymers: Derivatives such as Hydroxypropyl Cellulose (HPC) also serve as effective dry binders.

- Polyvinylpyrrolidone (PVP) and Copovidone: These are frequently employed, with various grades offering diverse binding behaviors. Copovidone, in particular, has demonstrated favorable properties for achieving larger granule sizes and minimizing fine particle fractions.

- Starch: A traditional and effective binder.

- Sugars: Such as mannitol, which can function as both a filler and a binder, especially beneficial for moisture-sensitive APIs.

Influence of Binder Properties:

The selection and inherent properties of the binder profoundly impact various granule and tablet characteristics, including granule size, fine particle fraction, tablet tensile strength, friability, and even disintegration time.

The particle size of the binder itself can also play a critical role

Common Fillers:

Widely used fillers include lactose, microcrystalline cellulose, dibasic calcium phosphate, and mannitol.

Addressing Process Limitations

Despite its numerous advantages, dry granulation presents several challenges that require careful consideration and strategic solutions:

1. Compression Issues (Loss of Compactibility)

One common challenge is the potential loss of compactibility in the final tablets compared to the ungranulated powders. This phenomenon often arises from:

- Granule Hardening: Excessive compaction force during granulation can produce overly hard granules that resist further compression during the subsequent tableting stage, leading to weaker tablets.

- Lubricant Sensitivity: Lubricants can become more effective on the surface of harder granules, impeding proper bonding between particles.

- Over-granulation: Producing excessively hard granules can result in common tableting defects such as capping, chipping, and lamination during the tablet pressing process.

Strategies to Address Compression Issues:

- Optimize Compaction Force: It is crucial to identify and apply the optimal compaction force that achieves sufficient densification without over-hardening the granules.

- Superdisintegrants: Incorporating superdisintegrants intra-granularly can promote the rapid fragmentation of granules during tableting, thereby increasing the bonding surface area and improving tablet strength.

- Material Properties: A thorough understanding of the deformation behavior of the materials involved is essential for effective process control.

2. Temperature Effects

While dry granulation avoids external heat, the mechanical compression process itself can generate heat. This necessitates careful consideration for:

- API/Excipient Stability: Elevated temperatures can adversely affect the stability of heat-sensitive APIs and excipients.

- Material Properties:A thorough understanding of the deformation behavior of the materials involved is essential for effective process control.

- Temperature changes can influence the flowability and compactability of the materials.

- Residual Moisture: Heat generation can exacerbate issues related to residual moisture within the formulation.

3. Endpoint Detection

Determining the precise endpoint of granulation can be challenging due to the absence of robust, quantifiable parameters.

4. Assessing Intermediate Quality

Ensuring the quality of intermediate granules is paramount for predicting the quality of the final product.

5. Scale-Up Challenges

Batch processes often encounter scale-up challenges due to variations in equipment geometry and process dynamics when transitioning from laboratory to commercial production.

6. Monitoring and Control in Continuous Processing

The increasing adoption of continuous manufacturing processes demands relevant and timely process monitoring capabilities.

Practical Case Examples

Low Dissolution in Dry Granulation

Problem: Achieving optimal dissolution profiles, especially for poorly soluble APIs (BCS Class II), can be a significant hurdle with dry granulation.

Case Example (Eplerenone): A comparative study involving Eplerenone 50 mg tablets revealed that while dry granulation met minimum dissolution specifications, its dissolution profile was notably lower than both the reference product and a wet-granulated counterpart. This suggests that the high compaction forces inherent in dry granulation can lead to denser granules with reduced surface area, thereby impeding drug release.

Solution/Implication: For poorly soluble drugs, careful formulation adjustments, such as the judicious selection of excipients (e.g., superdisintegrants, highly soluble fillers), or even considering alternative granulation methods, may be necessary to optimize dissolution performance.

Floating Granules/Tablets in Dry Granulation

Application: Dry granulation offers a versatile approach for developing specialized dosage forms, such as floating tablets for gastroretentive drug delivery systems.

Case Example (Moisture-Activated Dry Granulation – MADG): A study successfully utilized Moisture-Activated Dry Granulation (MADG) to develop gastroretentive placebo tablets. The granulates produced through this method resulted in floating tablets characterized by a short floating lag time and an extended floating duration. This exemplifies how dry granulation techniques can be effectively employed to create granules with precisely controlled properties, such as density and porosity, to achieve specific functionalities required for advanced drug delivery systems.

Conclusion

Dry granulation stands as a versatile and indispensable technique in pharmaceutical manufacturing, particularly for handling moisture- and heat-sensitive materials. While it offers numerous advantages, it also presents unique challenges related to process control, material properties, and ultimate product performance. A profound understanding of formulation factors, the nuances of equipment choices (slugging versus roller compaction), the critical role of binders and fillers, and proactive strategies to mitigate process limitations are all paramount for successful implementation. By diligently optimizing each stage and drawing insights from practical case examples, manufacturers can effectively leverage dry granulation to consistently produce high-quality pharmaceutical products with enhanced efficiency and reliability.

6 Must-Know Pharmaceutical Granulation Techniques for Superior Solid Dosage Forms