Benchmarking is a vital strategic tool that enables organizations to measure their processes, performance, and practices against those of industry leaders or competitors. In the pharmaceutical industry, where innovation, quality, and compliance are critical, benchmarking is a compass for achieving operational excellence and maintaining a competitive edge. This article explores the essence of benchmarking, its importance, advantages, types, processes, tools, and its profound impact on the pharmaceutical industry.

What is Benchmarking?

It compares an organization’s operations, processes, or performance metrics against industry best practices or competitors. It is not only about identifying gaps but also about learning and adapting strategies to improve overall efficiency and effectiveness.

Why do organizations need Benchmarking?

Organizations engage in benchmarking for various reasons:

1. Identify Performance Gaps:

To pinpoint areas where improvements are necessary. Performance gaps occur when there is a measurable difference between the current state of a company’s processes, products, or services and the ideal state defined by industry standards or competitors. Benchmarking enables organizations to:

- Quantify Inefficiencies: By comparing metrics like production output, cycle times, or compliance rates, companies can identify bottlenecks or weak links in their operations.

- Prioritize Improvements: It helps focus resources on areas with the highest potential for impact, such as quality control, R&D, or supply chain management.

- Enhance Competitive Advantage: Recognizing underperforming aspects of operations allows organizations to realign strategies and outperform competitors.

- Drive Innovation: Companies can adopt cutting-edge practices by learning from industry leaders.

2. Innovation:

Innovation is the cornerstone of growth in any industry, especially in pharmaceuticals, where advancements lead to breakthrough therapies. Benchmarking fosters innovation by:

- Exposing Best Practices: Studying successful companies reveals innovative techniques, such as the use of AI in drug discovery or continuous manufacturing technologies.

- Adapting to Market Trends: it ensures companies are aligned with the latest trends, such as personalized medicine or green chemistry.

- Cross-Industry Insights: Functional or generic benchmarking inspires other industries, like applying lean manufacturing from the automotive sector to pharma production.

- Enhance Quality: Essential in a regulated industry like pharmaceuticals, where patient safety is paramount.

3. Quality:

Quality is non-negotiable in pharmaceuticals due to its direct impact on patient health. Benchmarking plays a vital role in ensuring high standards by:

- Ensuring Compliance: Comparing practices against regulatory guidelines like Good Manufacturing Practices (GMP) helps maintain adherence to global standards.

- Reducing Defects: By understanding quality benchmarks, companies can minimize variability in drug formulations or packaging errors.

- Improving Patient Outcomes: Higher quality products lead to better efficacy, reduced side effects, and increased trust among healthcare providers and patients.

- Achieve Cost Efficiency: Identifying inefficiencies and optimizing resource allocation.

4. Cost management:

Cost management is crucial in the pharmaceutical industry, where R&D investments and regulatory hurdles can inflate expenses. Benchmarking aids in achieving cost efficiency by:

- Streamlining Processes: Identifying and adopting best practices reduces waste and improves resource utilization.

- Optimizing the Supply Chain: Benchmarking against efficient supply chain models can lower procurement costs and enhance inventory management.

- Foster a Culture of Continuous Improvement: Encourage a mindset of learning and growth.

5. Continuous improvement:

Continuous improvement is essential for long-term success, and it is a catalyst for fostering this culture by:

- Promoting Accountability: Regular comparisons encourage teams to strive for measurable progress.

- Encouraging Innovation: Employees are motivated to think creatively and propose changes that align with best practices.

- Enhancing Engagement: Involving staff in benchmarking activities empowers them and reinforces their role in achieving organizational goals.

- Building Resilience: Organizations with a mindset of continuous improvement are better equipped to adapt to changes in market conditions or regulations.

Advantages of Benchmarking

- Improved Decision-Making: Data-driven insights lead to better strategic decisions.

- Enhanced Performance: Aligning with best practices helps improve efficiency and output.

- Regulatory Compliance: Benchmarking against industry standards ensures adherence to regulations.

- Customer Satisfaction: Delivering superior products and services boosts trust and loyalty.

- Innovation Stimulation: Exposes organizations to new ideas and methods.

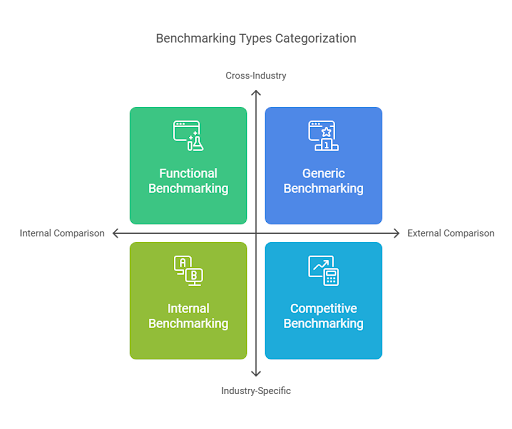

Types of Benchmarking

It is a versatile tool that can be applied in various ways depending on the focus and scope of the analysis. Here are the main types of benchmarking, each serving a unique purpose:

1. Internal:

- What It Is: Comparing performance, processes, or practices within the same organization, typically across different departments, teams, or locations.

- When to Use: When you want to identify best practices within your organization or standardize processes across multiple units.

- Example: A retail chain compares sales performance between its stores to identify top-performing locations and replicate their strategies.

2. Competitive:

- What It Is: Analyzing direct competitors to understand their strengths, weaknesses, and performance metrics.

- When to Use: When you want to gauge your position in the market and identify areas where you can outperform competitors.

- Example: A smartphone manufacturer compares its product features, pricing, and customer satisfaction ratings with those of its main rivals.

3. Functional:

- What It Is: Comparing specific functions or processes with those of organizations outside your industry that excel in similar areas.

- When to Use: When you want to innovate or improve a specific process by learning from leaders in other sectors.

- Example: A hospital studying the customer service practices of a luxury hotel chain to improve patient experience.

4. Strategic:

- What It Is: Analyzing the long-term strategies and success factors of industry leaders or top-performing companies.

- When to Use: When you want to redefine your business strategy or gain a competitive edge in the market.

- Example: A startup studying the growth strategies of a successful tech giant to shape its expansion plans.

5. Performance:

- What It Is: Comparing quantitative metrics (e.g., productivity, efficiency, quality) with industry standards or competitors.

- When to Use: When you want to measure your performance against external benchmarks and identify gaps.

- Example: A manufacturing company compares its production output and defect rates with industry averages.

6. Process:

- What It Is: Focusing on specific processes to identify best practices and improve efficiency, quality, or cost-effectiveness.

- When to Use: When you want to optimize a particular workflow or operational process.

- Example: A logistics company analyzing the supply chain processes of a market leader to reduce delivery times.

7. Product:

- What It Is: Comparing your products or services with those of competitors in terms of features, quality, pricing, and customer satisfaction.

- When to Use: When you want to enhance your product offerings or identify areas for innovation.

- Example: A car manufacturer compares the fuel efficiency, design, and technology of its vehicles with those of competitors.

8. Financial:

- What It Is: Comparing financial metrics (e.g., revenue, profit margins, ROI) with industry peers or competitors.

- When to Use: When you want to assess your financial performance and identify areas for improvement.

- Example: A small business compares its profit margins with those of similar-sized companies in the same industry.

9. Global:

- What It Is: Comparing your performance or practices with global industry leaders or standards.

- When to Use: When you operate in a global market or aspire to compete internationally.

- Example: A software company comparing its development processes with those of a global tech leader like Google or Microsoft.

10. Best-in-Class:

- What It Is: Studying the practices of organizations that are recognized as leaders in a specific area, regardless of industry.

- When to Use: When you want to adopt world-class practices and achieve excellence in a particular function.

- Example: A customer service team studying the practices of companies known for exceptional customer support, such as Amazon.

Choosing the Right Type of Benchmarking

The type of benchmarking you choose depends on your goals:

- Internal Benchmarking is ideal for improving consistency within your organization.

- Competitive Benchmarking: Analyzing performance relative to direct competitors.

- Functional or strategic benchmarking is useful for innovation and long-term growth, as well as comparing processes with organizations in the same function but in different industries.

- Performance or Process Benchmarking is best for optimizing specific metrics or workflows by Focusing on the best general practices applicable across various industries

By selecting the appropriate benchmarking type, you can focus your efforts on the areas that will deliver the most value to your business.

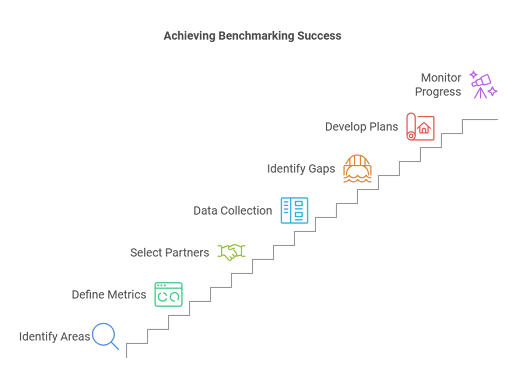

The Benchmarking Process

- Identify Areas for Benchmarking: Select processes, products, or functions critical to organizational success.

- Define Metrics and Objectives: Determine key performance indicators (KPIs) for comparison.

- Select Benchmarking Partners: Choose organizations or industry leaders for comparison.

- Data Collection and Analysis: Gather and analyze relevant data using qualitative and quantitative methods.

- Identify Gaps and Opportunities: Highlight discrepancies and potential areas for improvement.

- Develop Action Plans: Create strategies to close gaps and implement best practices.

- Monitor and Review: Continuously evaluate progress and adjust plans as necessary.

What are the tools used in Benchmarking?

- SWOT Analysis: Evaluates strengths, weaknesses, opportunities, and threats.

- Balanced Scorecard: Tracks performance across financial and non-financial metrics.

- Six Sigma Tools: Focuses on reducing variability and defects.

- SPC Charts: Statistical process control charts for monitoring processes.

- Benchmarking Databases: Industry-specific platforms offering comparative data.

- Process Mapping: Visual representation of workflows for analysis.

Impact of Benchmarking in the Pharmaceutical Industry

- Quality and Compliance: Adopting best practices ensures adherence to regulatory standards like GMP, GLP, and ISO certifications.

- Operational Efficiency: Streamlined processes reduce waste and improve time-to-market for new drugs.

- Cost Optimization: Helps identify and eliminate cost inefficiencies.

- Research and Development: Benchmarking innovative metrics accelerates drug discovery and development.

- Supply Chain Optimization: Enhances supplier relationships, logistics, and inventory management.

- Employee Engagement: Encourages a culture of learning and collaboration.

It is a transformative practice that provides pharmaceutical companies with the insights needed to stay ahead in a highly competitive and regulated environment. By identifying performance gaps and adopting best practices, organizations can achieve operational excellence, improve compliance, and foster innovation.