Objective

The objective of this article is to define the history, the desire to implement 5S, where it is needed to implement, and when it is required to implement. This article outlines the procedure for implementing 5S and presents multiple scenarios for production operations, highlighting the value of 5S in achieving operational excellence.

Introduction

“It is an approach to work systematically in production operations to smooth the process without hurdles.”

History

The concept was initiated in the mid-1980s by the automobile industry to maximize efficiency with respect to quality and to increase business profitability.

Composition

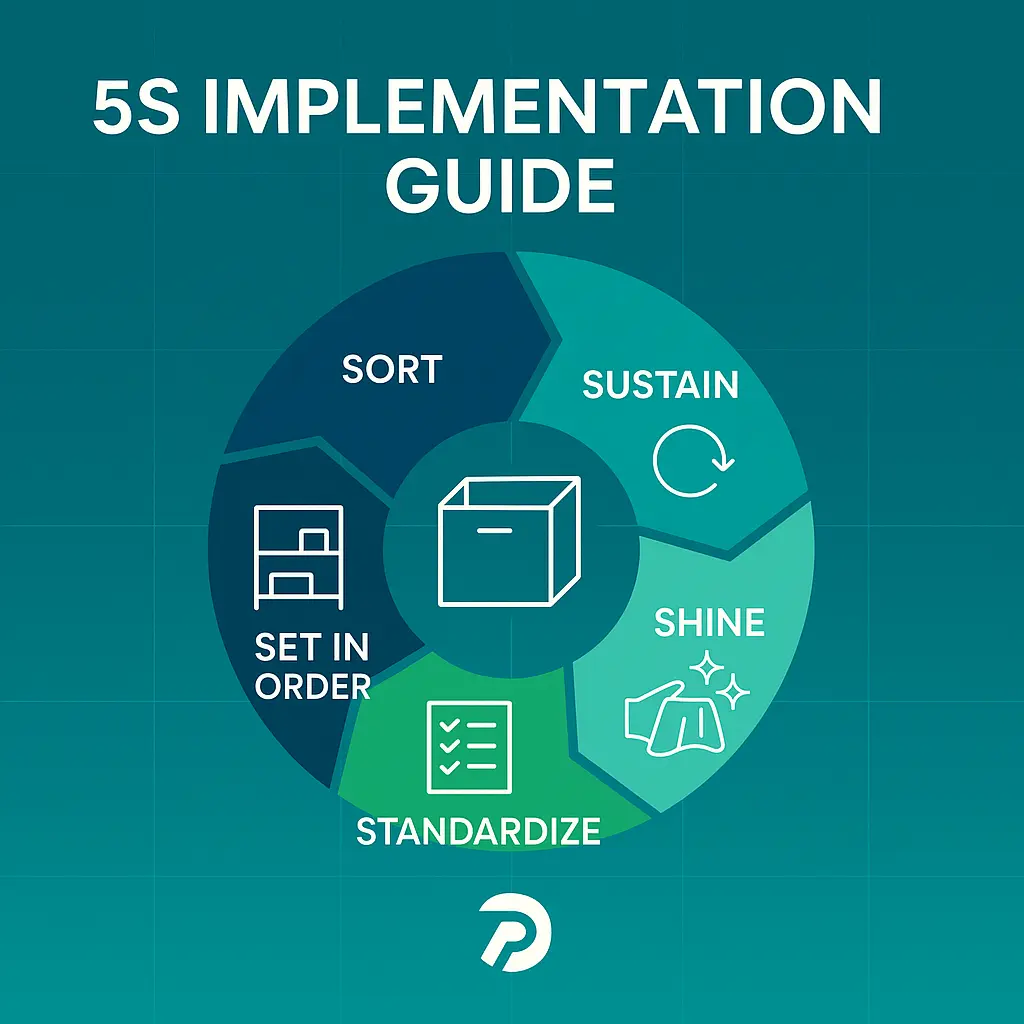

5S is composed of 5 standards, i.e., sort, set, shine, standardize, and sustain. In Japanese, it is represented as Seiri, Seiton, Seiso, SeiKetsu. This is basically the pillar of a composed production system.

Execution

5S can be implemented in an existing facility or a newly developed facility. it is implemented to achieve process improvement and efficiency, and to eliminate idle activities in production operations.

How 5S works

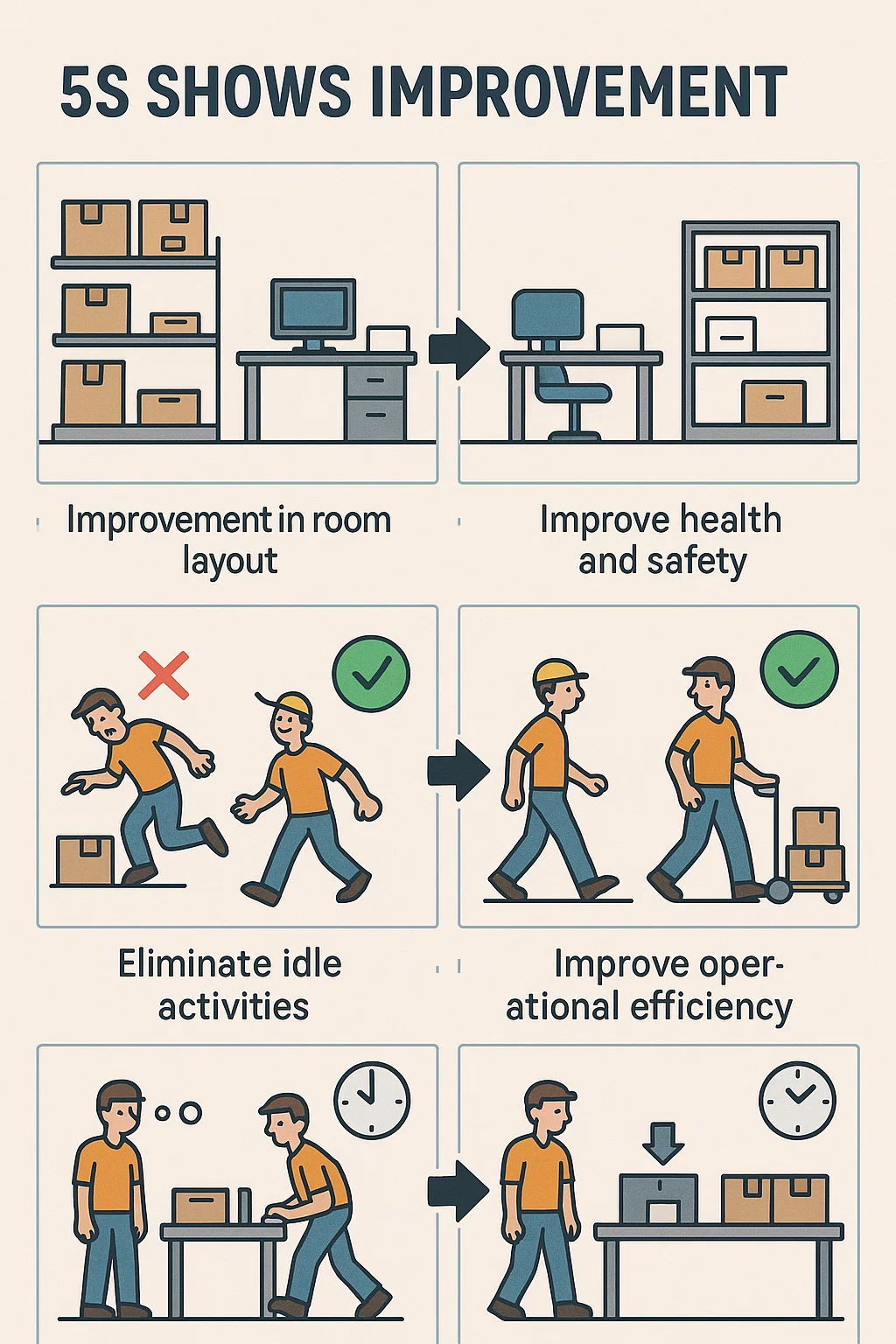

Improvement can be achieved in three to four ways.

- Improvement in room layout

- Improve health and safety

- Eliminate idle activities

- Improve operational efficiency

Motto of 5S in Operational Excellence

The main objective of 5S in operational excellence is to maximize utilization and output, minimize human effort and workload, and ensure smooth process execution.

Criteria

5S activities are carried out by a cross-functional team. On a production floor, this typically includes the following staff members.

- Production Manager

- Supervisor

- Operator

- Engineering representative

- Quality representative

1-Sort

Sort refers to the process of sorting. In terms of production, “it is defined as sorting of all irrelevant items and removal from the operational areas.”

Those items that are not required during operation should be removed at this stage.

How to Perform the Sorting Stage

Prepare a list of items required during the operation. This list will help identify any missing components that should have been available but were not at the time. It will help prevent waste, such as unnecessary movement to locate or arrange missing items.

All departmental representatives will review the listing.

Let’s assume it is a compression machine, and you are about to perform the sorting activity in the compression room.

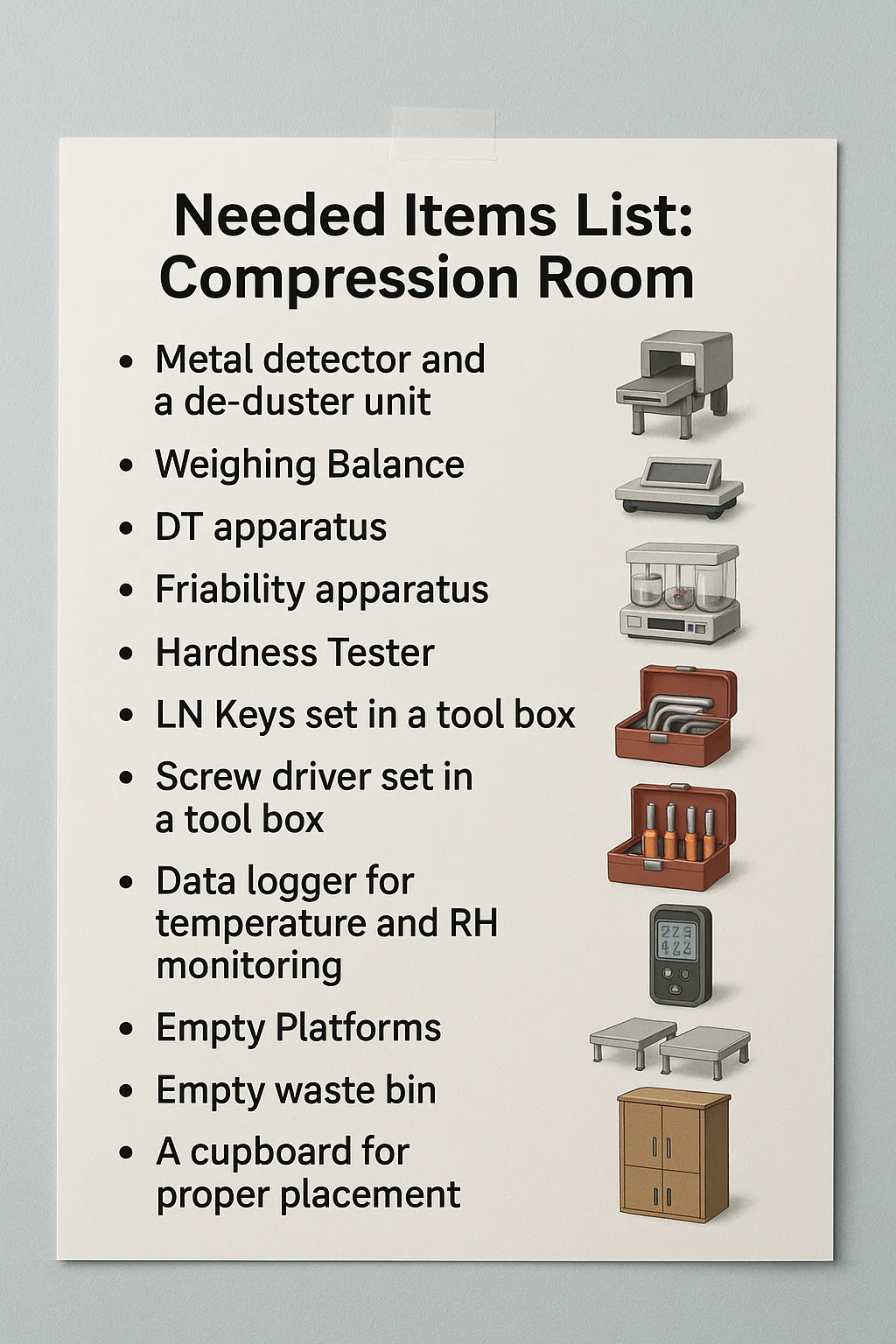

Needed Items List of a Compression Room

- A metal detector and a de-duster unit

- Weighing Balance

- DT apparatus

- Friability apparatus

- Hardness Tester

- LN Keys set in a toolbox

- Screwdriver set in a toolbox

- Data logger for temperature and RH monitoring

- Empty Platforms

- Empty waste bin

- A cupboard for proper placement

- Tablet for documentation

Irrelevant Items:

- Multiple sets of screwdrivers

- Rusted items

- Irrelevant items other than the needed items list

The rule of thumb is “If you are not utilizing any item on a daily basis, remove it; keep the things you are required only to get the job completed.”

Identification of Sorted items and How to sort

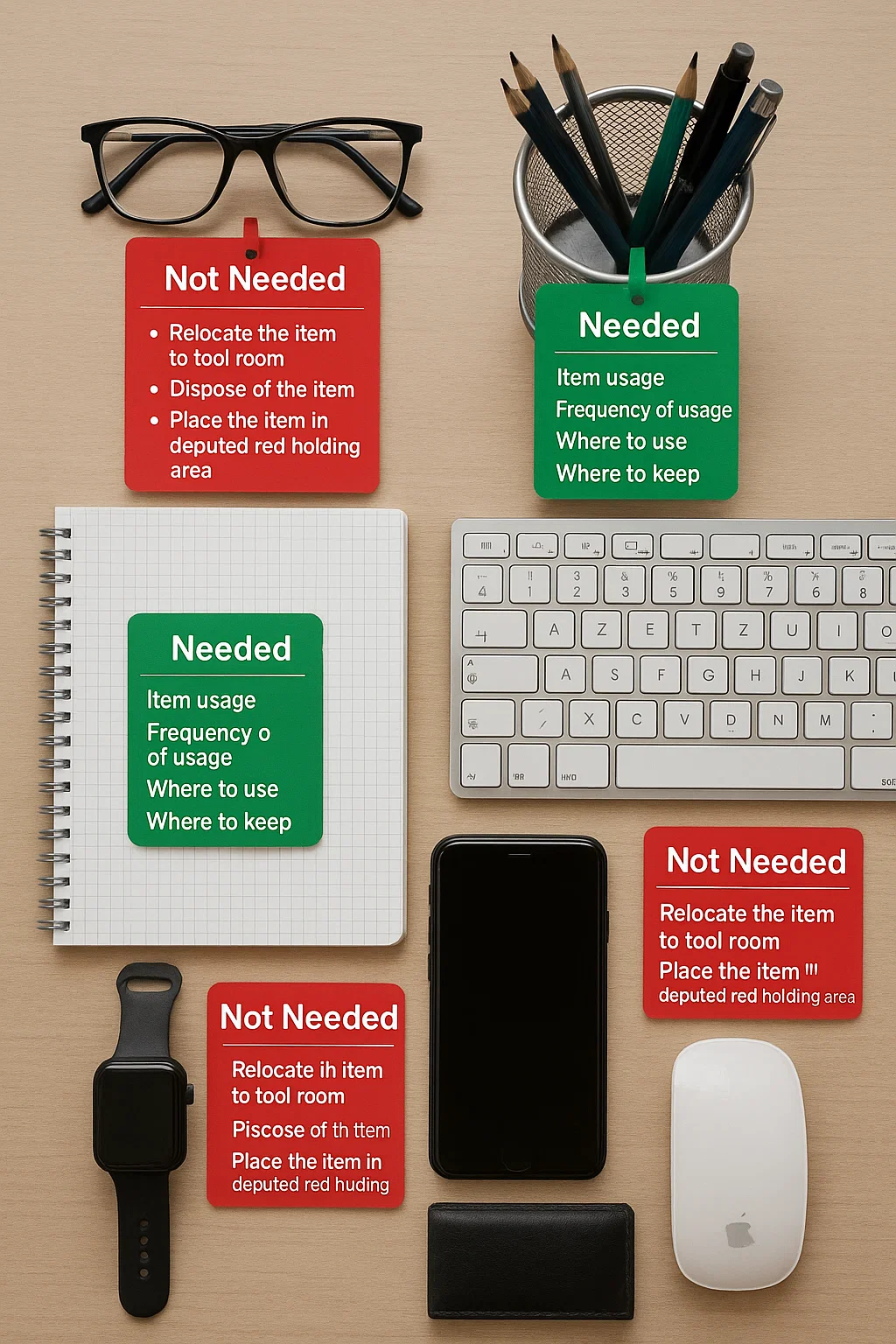

The Red Tag and Green Tag Step:

Paste the green tags on the items needed frequently on a daily basis to get the job done, and paste the red tags on the items not needed. This will actually comprise as following,

Green tags and red tags should bear a label as,

| GREEN TAG | RED TAG |

| Name of each functional member | Name of each functional member |

| Item usage | Relocate the item to tool room |

| Frequency of usage | Dispose of the item |

| Where to use | Place the item in the deputed red holding area |

| Where to keep |

This description will make easy decision-making and proper visualization of the sorting activity done by an experienced cross-functional team.

2-Set

Set is the second standard. In this standard, all items are properly set in order and allocated to their proper designated locations. This standard will make it easy to get the desired item on a needed basis. It is mandatory to have proper status labels.

How to Perform the Set Stage

Some important points need to be considered while executing the second standard.

- Proper demarcation needs to be done.

- All demarcation areas should be properly labelled

- All items must be placed in their dedicated demarked area.

- Arrange items in a proper way based on their usage. Items that are used more frequently should be placed closer within the workstation, while those used less often should be stored farther away.

- Remove unnecessary wiring spread on the floor to prevent any slip and trip hazard.

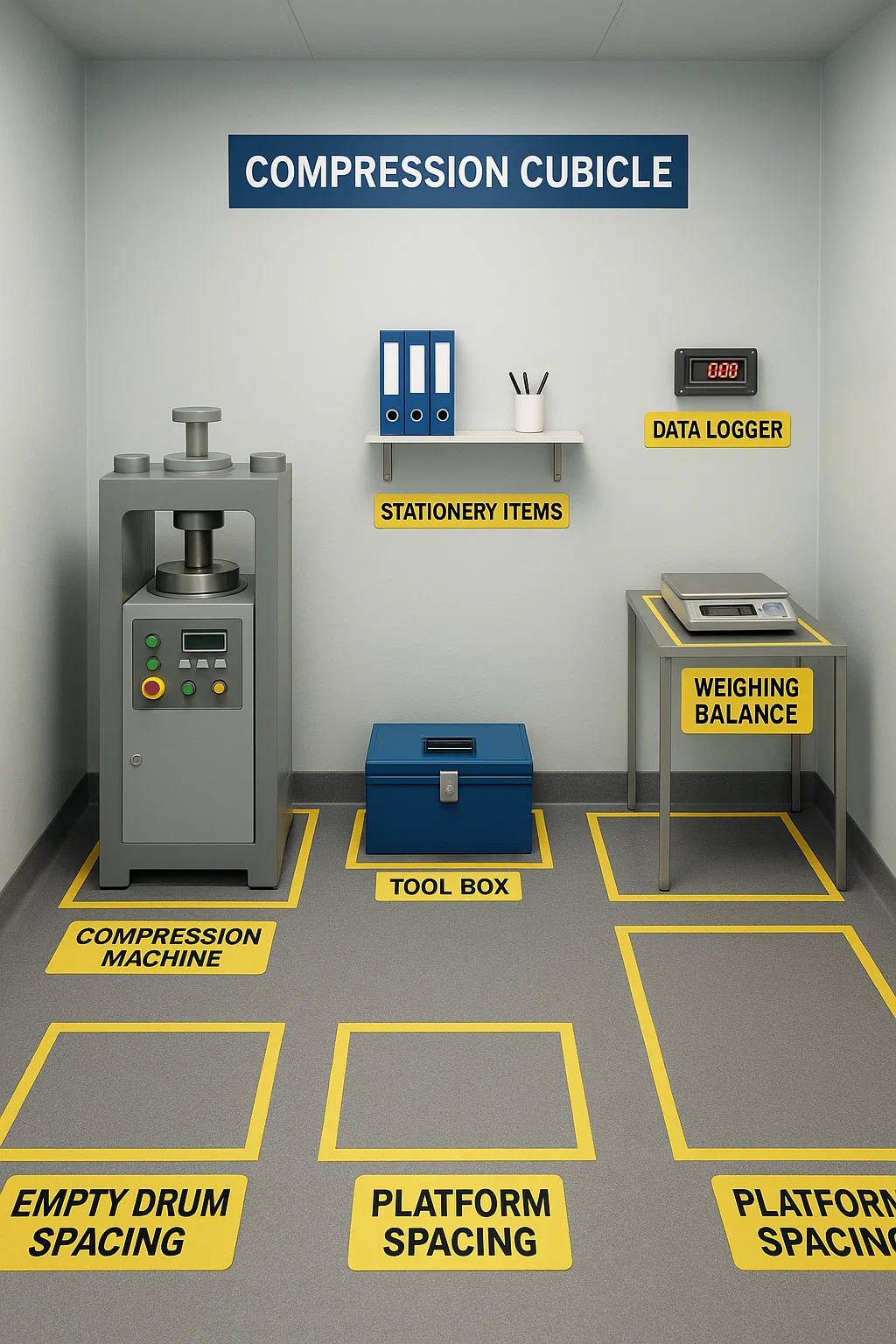

Practical Example of Set

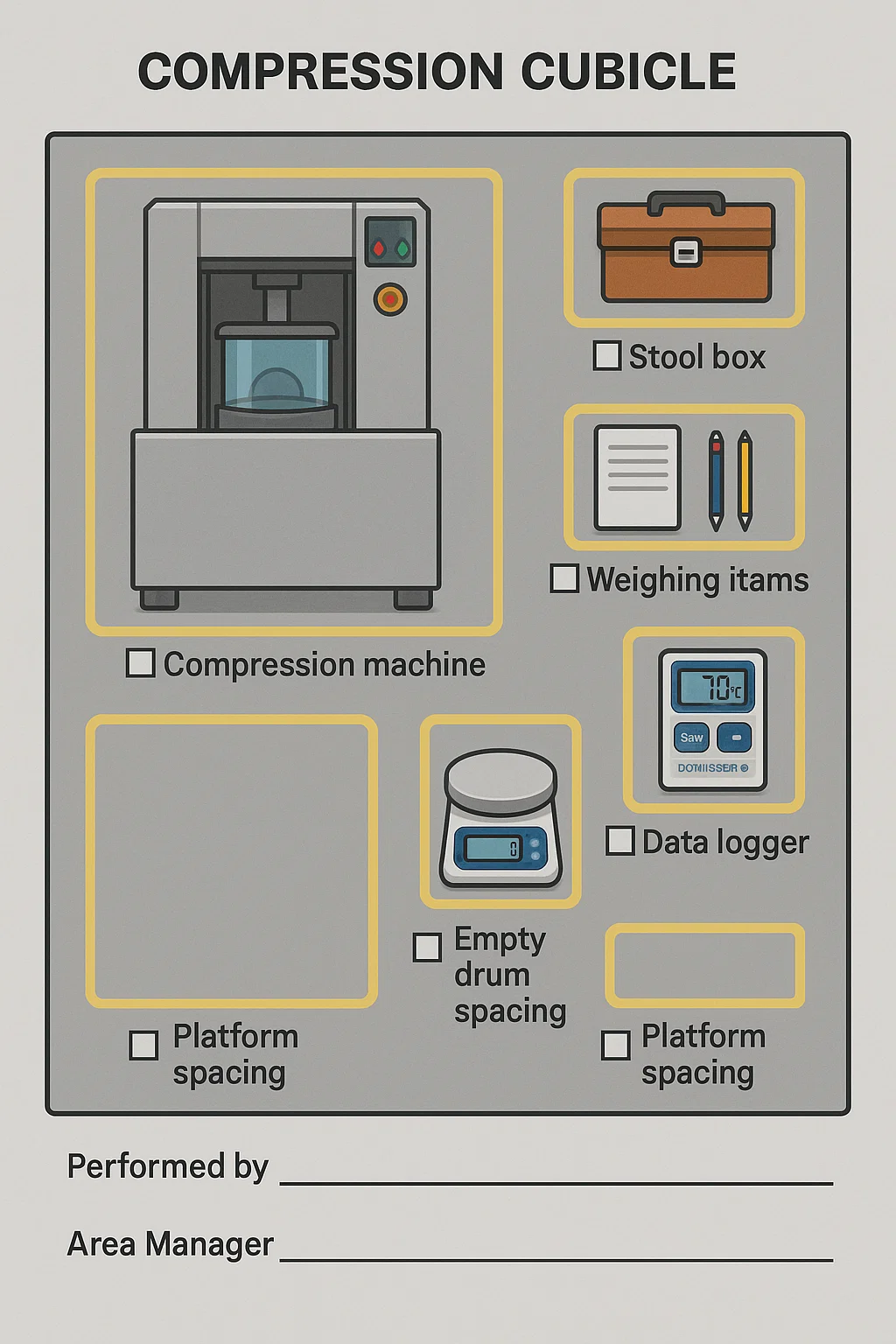

Let’s assume we have a compression cubicle,

Items to be set in a compression cubicle.

- Compression Machine

- Tool box

- Stationary items

- Weighing Balance

- Data Logger

- Empty drum spacing

- Platform spacing.

These items are used regularly and need to be set in the desired way. First is the proper demarcation of all the components placed in the room.

A toolbox is required daily, so it is just kept beside the compression machine. Stationery items and weighing balance are properly kept in their location. Proper zoning of items is also visible in the above image. This is how proper items are set in an ordered way.

This standard cannot be executed without the implementation of set.

3-Shine

The third standard is shine. Shine means free from dust, rust, and untidiness. All components placed in the cubicle are shining.

In simple words, this standard is about cleanliness. It is the step that needs to be maintained since the start, like floor mopping, machine, computer, table tops, table base, in-process equipment, bins, toolbox, and machine. All items are properly clean and shiny.

Benefits of keeping the items shining

- This standard helps to improve GMP

- This standard focuses on cleanliness to improve personal safety.

- There is no chance of contamination if the area is shiny after the implementation of 5S standard.

- Good working conditions, as workers would like to work in a clean and safe environment

- There is no chance of a slip and trip in the room as the sort and set standard has been implemented.

4-Standardize

Standardize is the 4th standard of 5S. This standard ensures that the 5S is properly maintained throughout the operation and the rest of the day.

How this Principle works, this principle will work simply that each person working there should be trained on 5S principle. A checklist to be developed to ensure that 5S, sort, set, and shine is properly implemented. This 5S is a reflection of good presentation of the area. The operator and supervisor are responsible for maintaining the 5S standards, while a random inspection from upper management and area managers is required as well.

There is an example of standardizing the 5S standard.

Create a checklist that includes a compression cubicle, comprising of compression machine, weighing balance, stationary items, Empty cleaned drums, platforms, a data logger, and Tool box.

Check List for standardization,

| Item | Set | Shine | Confirmed by | Checked by |

| Compression Machine | ||||

| Weighing balance | ||||

| Data logger | ||||

| Stationary Item | ||||

| Empty Cleaned Drums | ||||

| Platforms | ||||

| Tool Box |

This checklist will ensure that only required items are available, properly set in the cubicle, and properly shine. This will be confirmed by the area operator or supervisor. This will be checked by the area in charge or the manager.

5-Sustain: The Final Standard of 5S

This standard means that the initial 4S was successfully implemented in the area, and now the area is fully sustained with the improvements carried out in the initial standards of 5S.

There are several ways to sustain as mentioned below,

- Prepare colorful banners to share the importance of 5S

- Plan refresher training on 5S

- The checklist must be maintained by the area supervisor daily

- The checklist must be checked by the Section manager weekly

- Area visits must be done by the site head every week or every month to ensure 5S is in place

- A proper reward system to motivate the doers of 5S. This will increase the morale and force them to sustain 5S.

Conclusion

Implementation of 5S in organizations enhances the presentation of the sections and maintains the cGMP. The implementation of 5S eliminates the irrational movements and activities that result in process inefficiency. This process inefficiency causes an extra burden on the organization. Therefore, implementation of 5S directly improves productivity by reducing irrational movements and enhances process efficiency, quality by the step of sorting, setting, and shining, and safety. It produces an overall safe culture in the organization.